CMAI Covid Response

Salute to our healthcare teams for going beyond the call of duty to ensure safety for all. They have taken the shortage of PPE as a challenge and come up with tremendous solutions. They are tired. They are stretched. They are at risk. But they will not stop.

Dharmsinh Desai Memorial Methodist Heart Institute, Nadiad, Gujarat – 3-layered Mask (Revised Design)

The Dharmsinh Desai Memorial Methodist Heart Institute Nadiad in Gujarat is using non-woven polypropylene material to produce their own 3-layered Mask.

This is the revised design of their simple 3 layer masks made of waste cut pieces of non-woven material. 3 layers of 50-60 gsm

Dharmsinh Desai Memorial Methodist Heart Institute, Nadiad, Gujarat – Fitted 3-layered Mask (Modified Design)

The Dharmsinh Desai Memorial Methodist Heart Institute Nadiad in Gujarat is using non-woven polypropylene material to produce their own 3-layered Mask.

This is the Modified design of their simple 3 layer masks made of waste cut pieces of non woven material. 3 layers of 50-60 gsm.

In this they are using discarded wire to ensure proper fitting of the 3-layered mask.

Dharmsinh Desai Memorial Methodist Heart Institute, Nadiad, Gujarat – Donning of PPE (Revised)

In this video, you can see the healthcare worker putting on (donning) protective gear entirely produced by the hospital. (DDMM, Nadiad)

An observer should be always present while donning and doffing to ensure that the healthcare worker is adhering to the entire procedure as per the protocol.

Dharmsinh Desai Memorial Methodist Heart Institute, Nadiad, Gujarat – Doffing of PPE (Revised)

In this video, you can see the healthcare worker taking off (doffing) protective gear entirely produced by the hospital. (DDMM, Nadiad)

An observer should be always present while donning and doffing to ensure that the healthcare worker is adhering to the entire procedure as per the protocol.

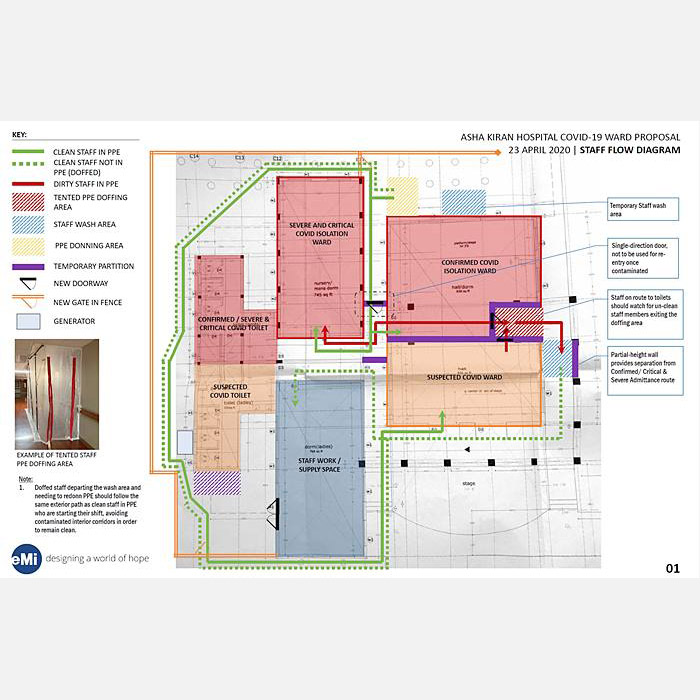

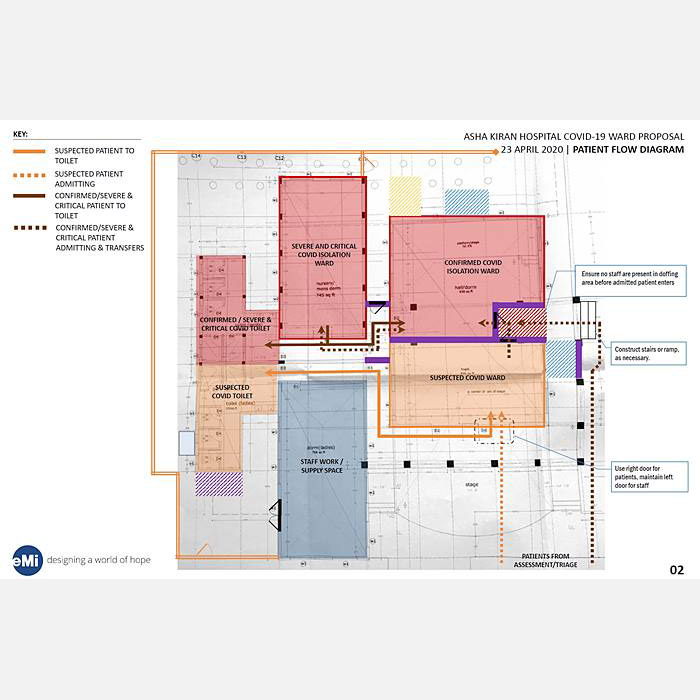

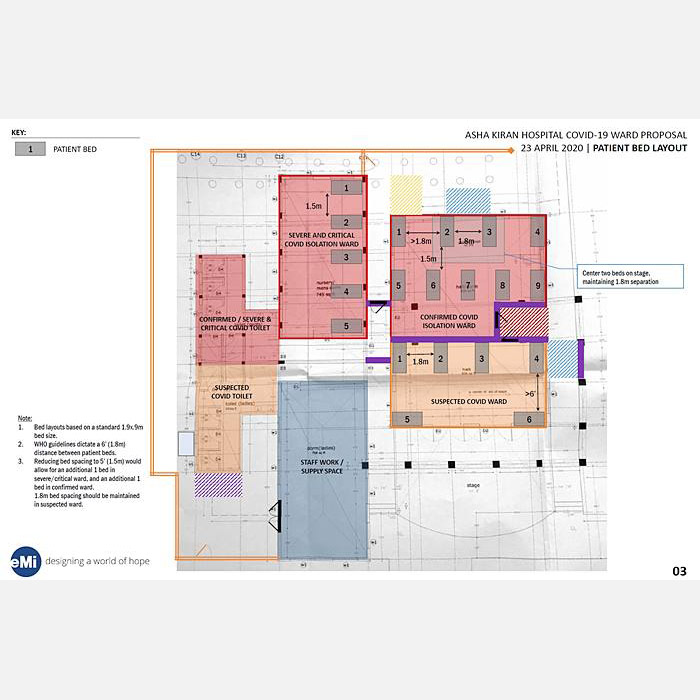

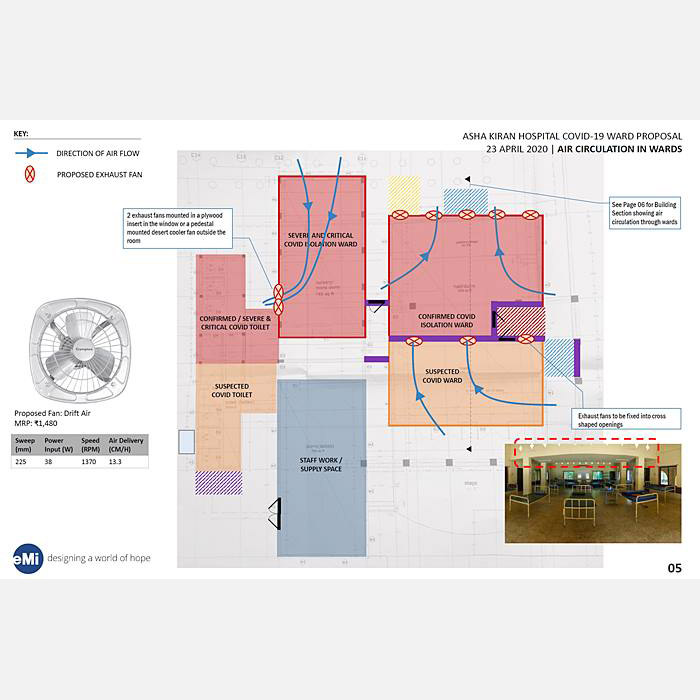

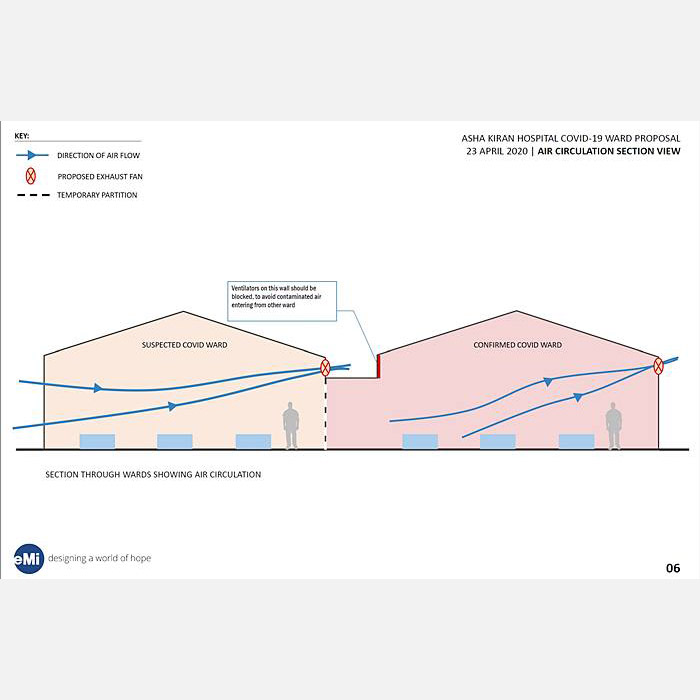

Asha Kiran Hospital, Lamtaput, Odisha – Converted their Training hall to Covid unit

Asha Kiran Hospital in Southern Odisha worked with Engineering Ministries International (EMI) to plan a conversion of their training hall and dormitory to a 20 bed COVID unit.

EMI provided the following design services:

- Suspected, Confirmed and Critical COVID Ward arrangement complete with bed layout

- Staff, Patient, and Laundry flow planning

- Retrofitting natural air ventilation system with forced exhaust fan selection and layout

Engineering Ministries International (EMI) is a non-profit Christian development organization made up of architects, engineers, surveyors, and construction managers who use their skills to serve the least reached worldwide. The EMI office in Delhi is offering complimentary design assistance to South Asian mission hospitals as they prepare to treat COVID patients during this crisis. Using technical guidance from the WHO specific to this coronavirus pandemic, EMI can work with hospital management to develop a plan to accommodate COVID patient, offering the following services:

- Layout nonclinical space or re-purpose existing clinical space as a COVID ward / unit

- Conversion of training halls, staff housing, corridors, etc.

- Safely maximize bed layout

- Design air ventilation per WHO guidelines

- Planning to minimize risk of infection of staff

- Staff & Patient flow

- Laundry & Equipment flow

If you want to discuss your hospital’s preparations for COVID patients with EMI, please email projects.india@emiworld.org

The Leprosy Mission Hospital, Shahdara, Delhi – Social Distancing in OPD

The TLM Shahdara, one of the urban hospitals in the outskirts of Delhi, providing quality Leprosy care and general services found an interesting way to ensure social distancing in the OPD by asking the patients not to use the red coloured (middle) seats.

The Leprosy Mission Hospital, Shahdara, Delhi – Tele counselling

TLM Shahdara has created a platform (a kind of call centre) to reach out to their patients during this difficult time.

From this platform the hospital staff calls the patients, and provides counselling related to Mental Health, continuation of medicine related to leprosy, care of ulcer, eye care, managing healthy life style, and Counselling for Diabetic patients.

Padhar Hospital, Betul, Madhya Pradesh – PPE Factory in their backyard

Padhar Hospital, a Mission hospital based in a village in Central India and have been around for more than 50 years. With the Pandemic striking and lack of access to PPEs, the hospital has started making their own PPEs and innovating in the process.

They have started making their own Cover-all and Face Shields. They are using motorcycle bubble shields, which are kept in place with cloth cap ties and sponge stuck over forehead and another type of Face Shield using photo album sheets, sponge and a drawstring.

Jalna Mission Hospital, Jalna, Maharashtra – Raincoat as PPE

The Jalna Mission Hospital healthcare workers wear Raincoats, cloth masks and any available resources as protective gear due to their lack of PPEs.

Makunda Christian Leprosy and General Hospital, Karimganj, Assam – Nursing school as PPE Factory

The Makunda Christian Leprosy and General Hospital is situated in a remote and predominantly tribal region of Karimganj District, Assam and also strategically located at the junction of the three states of Assam, Tripura and Mizoram. With the remoteness comes the challenge of availability of PPE.

That did not deter the hospital, the Nursing school stepped up, the students used their sewing skills to produce Masks and Gowns to protect their healthcare workers in the fight against Covid-19.

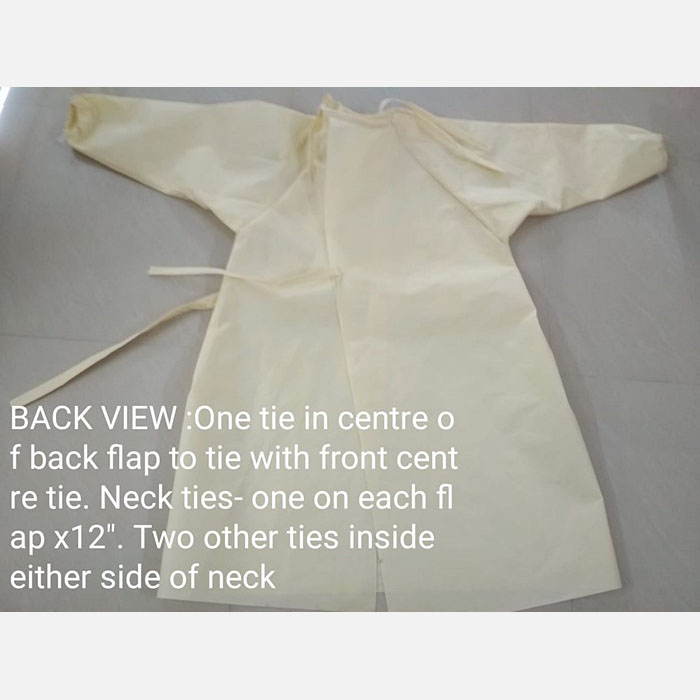

Christian Fellowship Hospital, Oddanchatram, Tamil Nadu – Making their own PPE

In preparation to fight Covod-19, CFH is manufacturing their own PPEs using cotton fabric and Polypropylene.

Shanti Bhavan Medical Centre, Simdega, Jharkhand – Layers of Protection using polyethylene

Shanti Bhavan Medical Centre has its beginning linked to the serious Malaria epidemic in the area in the late 1990s’where over 5000 people had died. Today the hospital finds itself in a larger Covid Pandemic. Located in the remote area with the challenge of non-availability of PPEs, the hospital decided to encounter the problem by bringing in several innovations like using of available resources and material to ensure protection for the healthcare worker be it knitted fabric or plastic covered Gown and polyethylene body covering.

Shanti Bhavan Medical Centre, Simdega, Jharkhand – Examination Shield

In order to create a barrier between the doctor and the patient so as to minimise contact between them, SBMC has made this Examination shield using folding curtain frame covered with polyethylene sheet.

Shanti Bhavan Medical Centre, Simdega, Jharkhand – Checking Temperature

In absence of Infrared thermo gun, the SBMC is using a wooden tray with a long handle to screen the patients/visitors coming into the hospital while maintaining social distance.

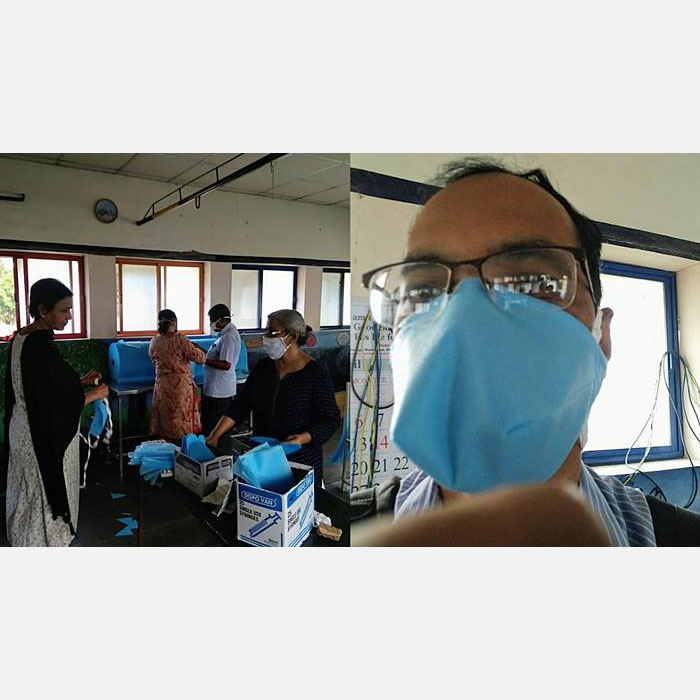

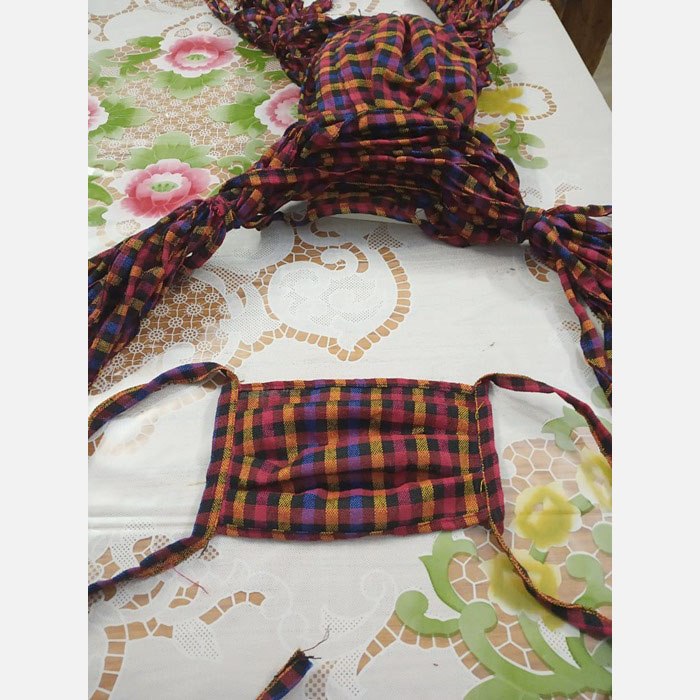

TLM Philadelphia Community Hospital, Salur, Andhra Pradesh -

To curb Community Spread of Covid, the hospital staff have started sewing face masks and donating it to the patients and the relatives. If more can be made, the whole community can be provided with these reusable, washable masks. Each person would require atleast 3-4 masks to be used during a week for the rest of the pandemic timeline.

Mary Lott Lyle's Hospital, Madanapalle, Andhra Pradesh – Making their own Sanitizer

With the shortage of Sanitizers in the market, MLL started making their own sanitizer as per the WHO Guidelines.

The cost is indigenously made sanitizer is just the fraction of the cost that is available in the market.

Ingredients used are:

- 5L spirit/Isopropyl

- 1L distilled water

- 75mL glycerol

- 400mL 3%Hydrogen peroxide

- 5mL Methylene Blue

Mary Lott Lyle's Hospital, Madanapalle, Andhra Pradesh – Making their own Sanitizer

With the shortage of Sanitizers in the market, MLL started making their own sanitizer as per the WHO Guidelines.

The cost is indigenously made sanitizer is just the fraction of the cost that is available in the market.

Ingredients used are:

- 5L spirit/Isopropyl

- 1L distilled water

- 75mL glycerol

- 400mL 3%Hydrogen peroxide

- 5mL Methylene Blue

Christian Hospital Bissamcuttack, Odisha – Making Cloth Mask for Hospital use

With the lockdown and shortage of PPEs especially masks, the CHB started producing their own cloth mask in the hospital premises and converted the nursing school into PPE factory.

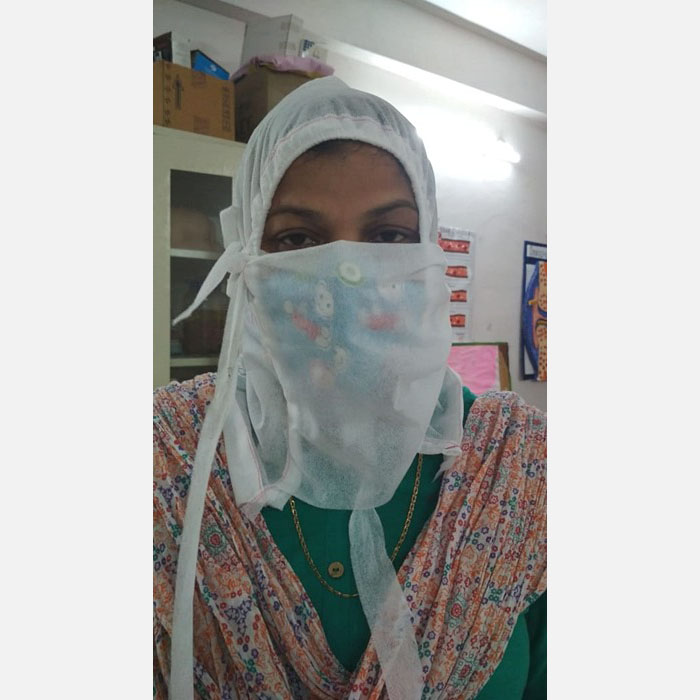

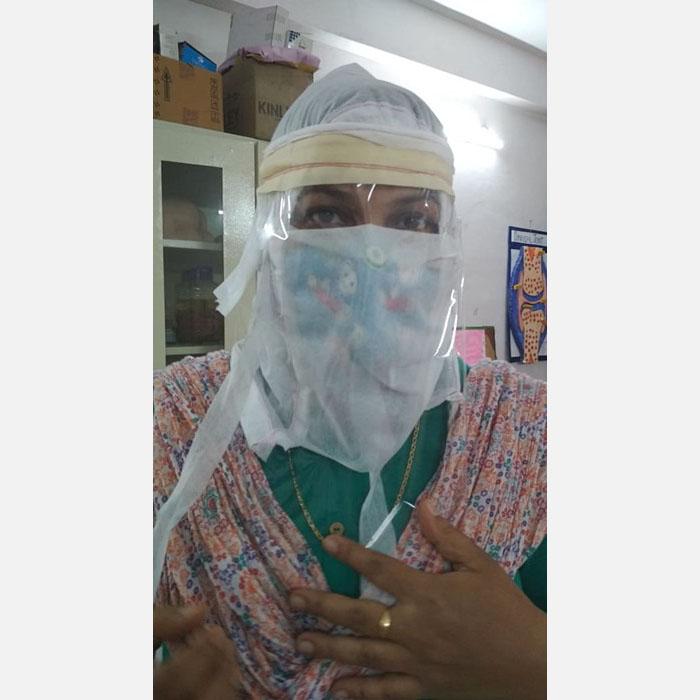

Christian Hospital Bissamcuttack, Odisha - Making Mask & Hood

In preparation to fight Covod-19, CBH is manufacturing their own PPEs using cotton fabric and Polypropylene

Christian Hospital Bissamcuttack, Odisha – The Bissamcuttack Initiative: A Mass Movement – Mask for All

In order to ensure that everyone in the block is protected, the CHB initiated the mass movement to ensure that every individual wears a mask when they come out of their houses.

They roped in all the professional tailors and the mothers with sewing machines to mass produce cloth mask in the villages. The target was to produce 10,000 masks. The with AFSA Club of Bissamcuttack partnered with CHB in this initiative.

Christian Hospital Bissamcuttack, Odisha – Making Cloth Mask for Hospital use

In order to protect the healthcare worker, the CHB has prepared their own Cover all gown with cloth.

These cover all provides protection to the healthcare worker from getting exposed to contaminants.

Christian Institute of Health Sciences and Research, Dimapur, Nagaland – Making their own PPE

The CIHSR is preparing their own own PPEs using Polypropylene sheet.

Dharmsinh Desai Memorial Methodist Heart Institute, Nadiad, Gujarat – Making their own Hood

Dharmsinh Desai Memorial Methodist Heart Institute of Gujarat is using nonwoven Polypropylene, which is available in the market to prepare their own hood.

They were able to perfect the design after several tries.

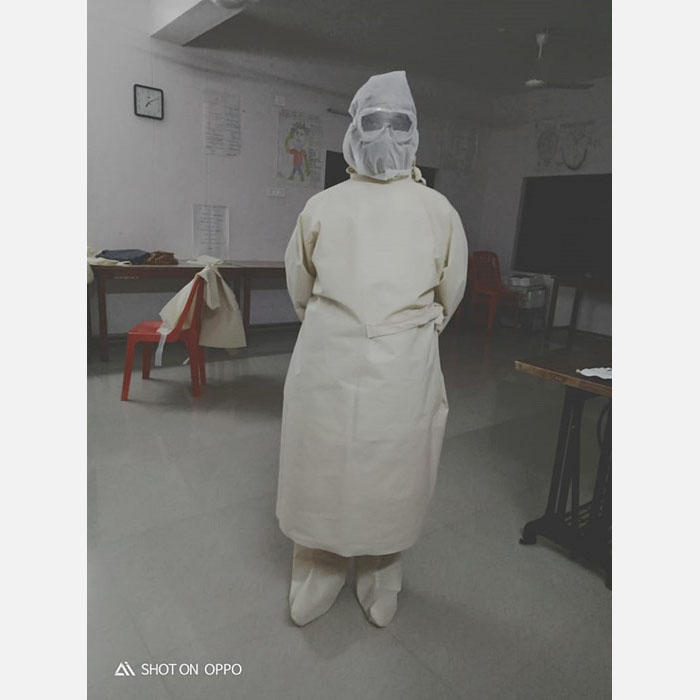

Dharmsinh Desai Memorial Methodist Heart Institute, Nadiad, Gujarat – Making their own Gown

Dharmsinh Desai Memorial Methodist Heart Institute of Gujarat is using 90 gsm non-woven Polypropylene to prepare their own Gown. They are using 63-inch-wide fabric to prepare these gowns.

They were able to perfect the design after several tries to reduce the contamination during donning and doffing process.

Dharmsinh Desai Memorial Methodist Heart Institute, Nadiad, Gujarat – Making their own 3-layered Mask

With the leftover material from the gown, the hospital is preparing a 3-layered mask. The hospital is ensuring that every inch of the fabric is used to prepare PPEs.

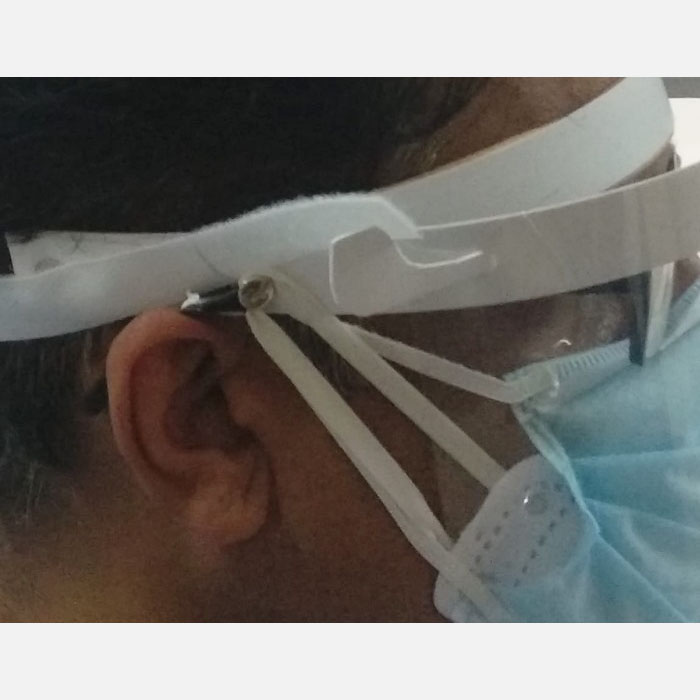

Dharmsinh Desai Memorial Methodist Heart Institute, Nadiad, Gujarat – Making of Visor

Using Transparency sheets, paper punch, adhesive tapes the hospital is able to produce low cost face shield or visor to protect the face of the healthcare worker.

Dharmsinh Desai Memorial Methodist Heart Institute, Nadiad, Gujarat – Demonstration of the full product.

In this video, you can see the healthcare worker putting on (donning) and taking off (doffing) protective gear entirely produced by the hospital.

An observer should be always present while donning and doffing to ensure that the healthcare worker is adhering to the entire procedure as per the protocol.

Lady Willingdon Hospital, Manali, Himachal Pradesh – Innovative Intubation Tent

To minimize this risk of exposure and infection, the Manali Hospital designed a simple intubation tent which can help minimize the aerosol dissemination risk to the operator. All other advocated measures, including personal protective equipment, N 95 masks, minimizing mask ventilation and early inflation of the balloon on the endotracheal tube are all to be practiced in addition to the use of this tent.

STEPS FOR USE:

- This tent can be made with clear plastic, with two sleeves in it into which the operator inserts his hands, and then puts on an extra pair of gloves, in addition to the ones he or she is already wearing as part of the PPE. The gloves go over the edges of the plastic sleeve ensuring a good seal.

- All equipment for intubation, including laryngoscope, suction, guedels airway, syringe for inflation of the cuff, and endo tracheal tube of the appropriate size are placed on the chest of the patient to be intubated.

- The edges of the plastic are tucked under the mattress on three sides of the head of the bed, and the inferior edge is tucked under the patients bedcovers, so no air will escape into the room onto the operator standing at the head end.

- The operator is able to see through the plastic to intubate the patient after the administration of appropriate relaxant via a peripheral iv access.

- After intubation the cuff is inflated, and the suction utilized to suck out the air in the tent prior to disassembly.

This way very little air from the patient will disseminate into the room to potentially infect caregivers.

Lady Willingdon Hospital, Manali, Himachal Pradesh – Simple Visor

Using simple plastic and Velcro, the Manali Hospital is preparing these functional visors for protection.

Madhipura Christian Hospital, Madhipura, Bihar – Raincoats as PPEs

Located in the small town in interiors of Bihar, the hospital does not have access to standard PPEs.

In order to continue to their commitment of providing services to the community, the hospital resorted to using raincoats/rain covers on top of the gowns to prevent exposure and infection.

Gems Polytechnic College, Aurangabad, Bihar – 3d Printing of Face Shield

A sister concern of the GEMS hospital in Aurangabad district of Bihar, the GEMS Polytechnic College designed and printed face shield using 3D printing technology in its labs.

The design has been shared with leading institution in Tamil Nadu for mass printing and helping a leading hospital in South to equip their doctors.

Herbertpur Christian Hospital, Dehradun, Uttarakhand – Making wearing mask less straining

Innovation from the orthotic and prosthetic department of the hospital in the form of fixing a small clamp on both side of the face shield, where the mask can be fixed. This makes it comfortable for the healthcare worker, who can wear the mask for longer period without any strain to the ears.

Head Quarters

CMAI

A-3, Local Shopping Centre, Janakpuri,

New Delhi - 110058, India

011-41003490 / 41064328

+91-11-255 98 150

cmai@cmai.org

Bangalore Office

HVS Court, 3rd Floor

21 Cunningham Road

Bangalore – 560052,

Karnataka

080 22205464, 22205837, 22257844

080 22205826

cmaiblr@cmai.org

Registered Office

CMAI

Christian Council Campus

NCCI Road, Civil Lines

Nagpur – 440001

Maharashtra